SCR 37kW Screw Air Compressor

European-Standard Technology | Built for Bangladesh Climate | Delivered by Global Cynax

If you are looking for a 37kW screw air compressor in Bangladesh that delivers high energy efficiency, stable performance, and long service life under continuous industrial operation, the SCR 37kW Screw Air Compressor is a reliable and cost-effective solution.

Global Cynax Bangladesh Ltd. is the authorized distributor of SCR Air Compressors in Bangladesh, providing genuine machines, factory-trained service engineers, original spare parts, and nationwide after-sales support.

Complete 37kW Compressed Air Solution – Optional All-in-One Package

The SCR 37kW system can be supplied as a complete compressed air solution for uninterrupted factory operation:

- 37kW Permanent Magnet VSD Screw Air Compressor

- High-Efficiency Refrigerated Air Dryer

- Pre-Filter & After-Filter

- Air Receiver / Pressure Vessel

This integrated system ensures stable pressure, clean & dry compressed air, lower electricity consumption, and long-term reliability for Bangladesh industries.

Why SCR 37kW Screw Air Compressor Is Ideal for Bangladesh

Bangladesh’s manufacturing plants typically run in extreme operating conditions—high humidity (often 80%+), high ambient temperatures (35–43°C), dusty production floors, and 16–24 hours of continuous operation. These factors combine to create a harsh environment for compressed air systems. In practice, many imported compressors that are not designed for tropical climates experience overheating, moisture-related faults (such as water carryover, corrosion, and electrical issues), and frequent nuisance shutdowns, leading to production interruptions and higher maintenance costs.

|

|

|

| High Humidity High humidity is a major challenge for continuous screw air compressor operation in Bangladesh, where relative humidity often exceeds 80% year-round. Excess moisture causes condensation inside the compressor and air system, resulting in corrosion, oil contamination, poor air quality, and frequent moisture-related faults. For process applications running 16–20 hours per day, unmanaged humidity can cause unexpected shutdowns, higher maintenance costs, and reduced equipment life. |

Dusty Production Floor

Dusty production floors are a common challenge in Bangladesh’s industrial environments and pose serious risks to continuous screw air compressor operation. Airborne dust can clog air filters, contaminate lubricant, reduce cooling efficiency, and accelerate wear of internal components, leading to overheating and unplanned shutdowns. For process applications running 24/7, effective filtration, sealed components, and dust-resistant design are essential to ensure stable performance, lower maintenance, and long service life. |

Ambient Temperature

High ambient temperature is a serious challenge for continuous screw air compressor operation in Bangladesh, where factory temperatures often reach 35–43°C. Under continuous process duty, excessive heat can cause overheating, reduced efficiency, frequent trips, and accelerated component wear, especially in compressors not designed for tropical conditions. Proper cooling and heat-resistant design are essential to ensure stable performance and uninterrupted operation in such environments. |

SCR compressors are engineered specifically for tropical, high-humidity conditions, making them a more reliable and practical choice for Bangladesh. Their design focus supports stable performance under heat load, better tolerance to moisture-heavy air, and dependable operation in dusty industrial settings. As a result, SCR compressors can operate smoothly across most manufacturing sectors—including textiles, garments, plastics, food processing, and general industrial plants—without the recurring problems commonly seen in non-tropical models.

For factories aiming to reduce downtime and keep production running consistently, SCR compressors are a smart, Bangladesh-ready solution.

Key Design Advantages:

- IP65 protection for motor and critical components

- IE4 Permanent Magnet motor (oil-cooled) for stable operation at high temperature

- Independent closed-loop cooling system for continuous duty

- Wide voltage tolerance to handle unstable power supply

- Low-RPM direct-drive airend for longer life and lower noise

✅ Result: Higher uptime, fewer breakdowns, and lower operating cost in Bangladesh conditions.

Industries Using SCR 37kW Screw Air Compressor

The SCR 37kW industrial air compressor is widely used in:

- Textile & Garments (Spinning, Weaving, Dyeing, Finishing)

- Pharmaceutical Industries

- Food & Beverage Processing

- Packaging & Printing

- Plastic & Injection Molding

- Ceramics & Tiles

- Light Engineering & Workshops

These industries benefit from constant pressure, reduced downtime, and energy savings.

Advanced Technology – European Performance at Practical Cost

SCR integrates European-level compressor technology while keeping investment and maintenance costs practical for Bangladesh factories.

Key Technology Features:

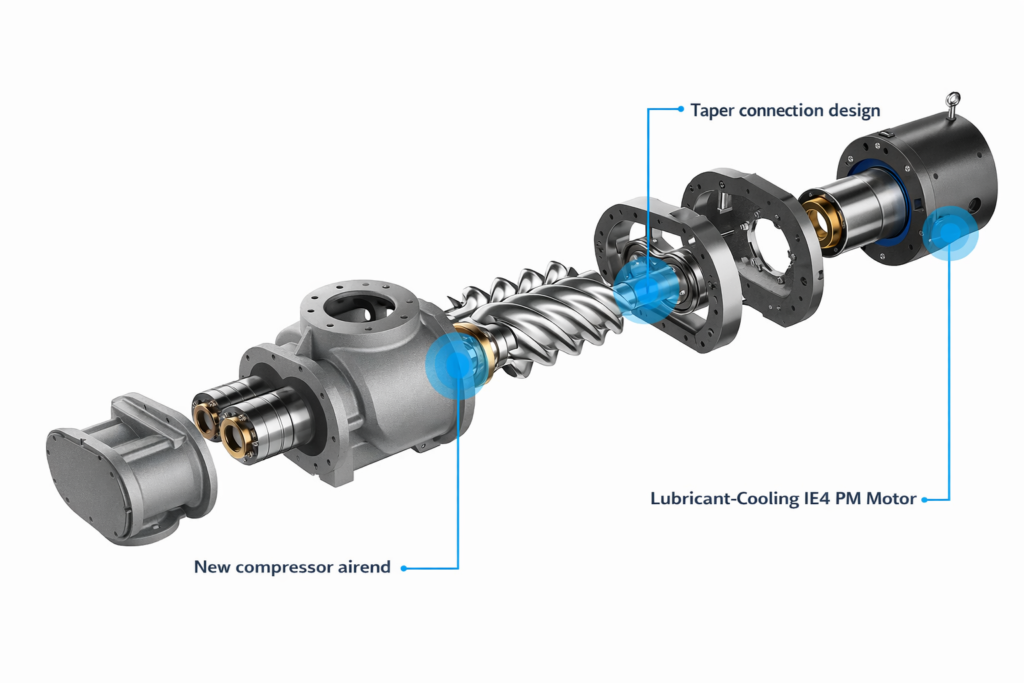

- IE4 Super-Premium Permanent Magnet Motor

- Direct Drive System (1:1 Taper Connection) – no belt, no gearbox

- Japanese-designed airend (R&D collaboration with Anest Iwata)

- Isothermal compression with multi-point oil injection

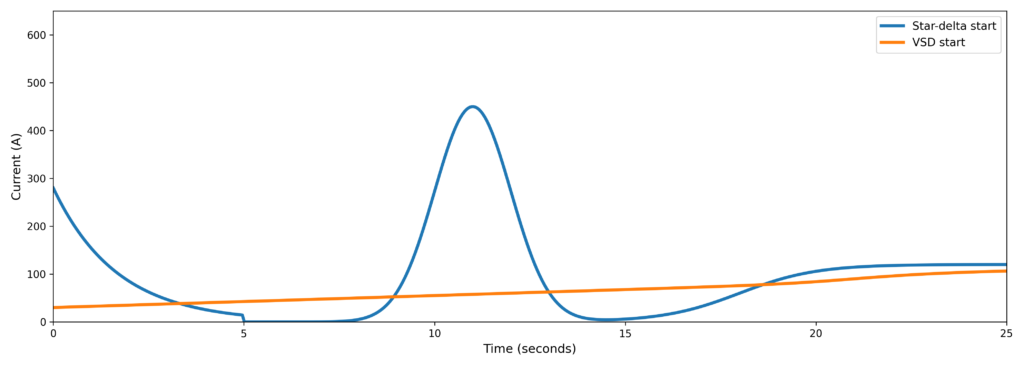

- Variable Speed Drive (VSD) for energy optimization

- Pressure stability up to ±0.01 MPa

- Oil carryover < 3 ppm

- 7-inch touch screen intelligent controller

- Modbus / RS485 communication

SCR vs Conventional European Compressors (37kW Class)

| Feature | SCR 37kW | Typical European Brand |

| Motor Efficiency | IE4 PM Motor | IE3 / IE4 |

| Drive System | Direct Drive (1:1) | Belt / Gear |

| VSD | Standard | Often Optional |

| Pressure Stability | ±0.01 MPa | ±0.02 MPa |

| Energy Saving | 30–40% | 25–30% |

| Spare Parts Cost | Low | Very High |

| Service Cost | Low | High |

➡️ Same performance, significantly lower life-cycle cost in Bangladesh.

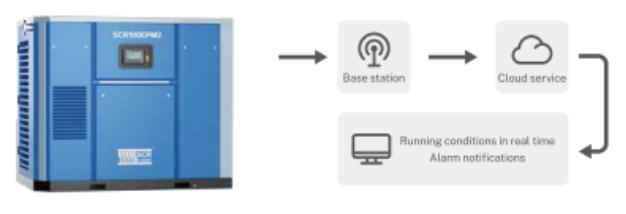

SCR’s Cloud Service Option – Advance IoT

As the authorized distributor of SCR compressors in Bangladesh, Global Cynax delivers a connected compressed-air solution that combines proven compressor performance with advanced IoT + cloud visibility. Monitor key operating conditions in real time, receive actionable alerts, and protect remote access with enterprise-grade security—so you can reduce unplanned downtime and improve maintenance planning.

🛰️ Real-Time Remote Monitoring

Monitor SCR compressor running conditions anytime, anywhere via cloud access. View key operational status and performance data in real time for faster decisions and better control.

🔔 Smart Alarm Notifications

Receive automatic alarms when abnormal conditions occur. Early alerts support preventive action and help avoid unplanned shutdowns.

🔗 Industrial Connectivity & Integration

Supports industrial communication for integration with plant systems (e.g., RS485 / Modbus RTU). Suitable for centralized monitoring and coordinated multi-compressor operation.

🔒 Secure VPN Cloud Access

Secure remote connectivity using VPN (Virtual Private Network)—providing security comparable to a private network. The cloud platform is designed to be user-friendly for operators and maintenance teams.

Low Maintenance & Lower Spare Parts Cost

The real cost of an air compressor is not the purchase price—it’s maintenance, spare parts, and downtime over 5–10 years.

SCR compressors are designed to reduce ownership cost:

- 30–50% lower spare parts cost than European brands

- Direct drive design → no belt, no gearbox

- Fewer wear parts = fewer failures

- Original SCR spare parts stocked locally by Global Cynax

✅ Result: Less downtime, faster service, and predictable operating cost.

Technical Specifications – SCR 37kW Screw Air Compressor

| Parameter | Specification |

| Motor Power | 37 kW |

| Motor Type | IE4 Permanent Magnet, Oil-Cooled |

| Drive Type | Direct Drive (1:1 Taper) |

| Working Pressure | 7 / 8 / 10 bar |

| Air Capacity | ~6.5 – 7.5 m³/min (approx.) |

| Controller | 7” Touch Screen, VSD |

| Oil Carryover | < 3 ppm |

| Protection Class | IP65 |

| Design Life | 100,000+ hours |

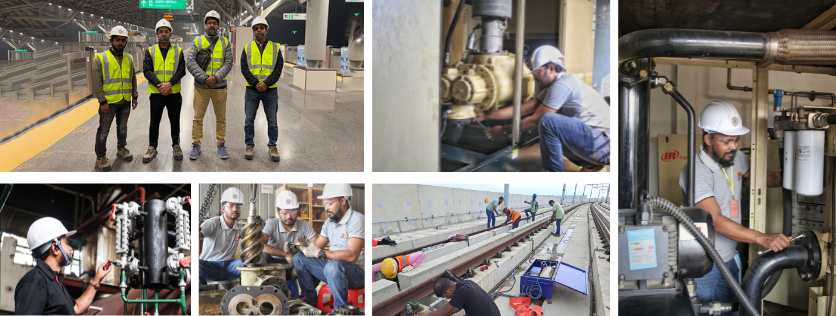

Strong After-Sales Support by Global Cynax

As the authorized SCR distributor in Bangladesh, Global Cynax ensures dependable after-sales support to keep your compressor running with minimum downtime. With a 17-member team of factory-trained engineers and technicians, we provide fast response, genuine spare parts, and complete service coverage for continuous industrial operation.

Our support includes:

- Factory-trained service engineers & technicians (17 members total)

- Dedicated service vehicles for quick site response

- Fast supply of genuine spare parts

- Preventive maintenance & emergency breakdown service

- AMC (Annual Maintenance Contract) options

- Service coverage in Dhaka & Chattogram

- Installation, commissioning & operator training

➡️ Result: minimum downtime and long-term peace of mind.

Why Buy SCR Compressor from Global Cynax?

✔ Authorized SCR distributor in Bangladesh

✔ Genuine SCR compressors & spare parts

✔ Nationwide service network

✔ Energy-efficient solutions

✔ Competitive pricing

✔ Long-term technical support

Contact Global Cynax Bangladesh Ltd.

Authorized SCR Air Compressor Distributor

📱 Mobile: +880 1786 100017

📧 Email: [email protected]

🌐 Website: www.globalcynax.com