European-Standard Technology | Built for Bangladesh Climate | Delivered by Global Cynax

If you’re looking for a 90kW screw air compressor in Bangladesh that combines European-level output, high energy efficiency, and long-term durability at a reasonable cost, the SCR 90kW Screw Air Compressor (Complete Package) is an excellent fit for your facility. Whether your operation is in textile & garments, pharmaceuticals, food & beverage, or any other manufacturing sector, SCR can be a dependable compressed air solution. Its robust design and construction are well-suited to Bangladesh’s climate and demanding industrial conditions.

Global Cynax Bangladesh Ltd. is the authorized distributor of SCR Air Compressors in Bangladesh, ensuring you receive genuine products, supported by factory-trained service engineers, original spare parts, and nationwide after-sales support.

Complete 90kW Compressed Air Solution (All-in-One Package)

The SCR 90kW Screw Air Compressor Complete Package is a fully engineered industrial compressed air system designed for continuous factory operation. The package includes:

- 90kW Permanent Magnet VSD Screw Air Compressor

- High-Efficiency Refrigerated Air Dryer

- Industrial Line Filters

- Air Receiver / Pressure Vessel

This complete system ensures stable pressure, clean & dry compressed air, lower electricity consumption, and long-term reliability for Bangladesh industries.

Why SCR Screw Air Compressor Is The Best for Bangladesh Climate

Bangladesh is one of the most challenging environments for industrial air compressors. Factories operate in high humidity (often above 80%), high ambient temperatures (35–43°C), and dusty production floors, while also dealing with voltage fluctuation and running compressors for 20–24 hours per day. In these conditions, many imported compressors—especially those not designed for tropical climates—can suffer from overheating, moisture-related faults, frequent shutdowns, and higher maintenance costs.

|

|

|

| High Humidity High humidity is a major challenge for continuous screw air compressor operation in Bangladesh, where relative humidity often exceeds 80% year-round. Excess moisture causes condensation inside the compressor and air system, resulting in corrosion, oil contamination, poor air quality, and frequent moisture-related faults. For process applications running 16–20 hours per day, unmanaged humidity can cause unexpected shutdowns, higher maintenance costs, and reduced equipment life. |

Dusty Production Floor

Dusty production floors are a common challenge in Bangladesh’s industrial environments and pose serious risks to continuous screw air compressor operation. Airborne dust can clog air filters, contaminate lubricant, reduce cooling efficiency, and accelerate wear of internal components, leading to overheating and unplanned shutdowns. For process applications running 24/7, effective filtration, sealed components, and dust-resistant design are essential to ensure stable performance, lower maintenance, and long service life. |

Ambient Temperature

High ambient temperature is a serious challenge for continuous screw air compressor operation in Bangladesh, where factory temperatures often reach 35–43°C. Under continuous process duty, excessive heat can cause overheating, reduced efficiency, frequent trips, and accelerated component wear, especially in compressors not designed for tropical conditions. Proper cooling and heat-resistant design are essential to ensure stable performance and uninterrupted operation in such environments. |

SCR Screw Air Compressors are engineered specifically for tropical, high-humidity countries like Bangladesh, combining European-level efficiency with durability built for local weather and operating realities. Key design advantages include:

- IP65 protection for motor and critical components (better resistance to dust and moisture)

- IE4 Permanent Magnet motor (oil-cooled) to maintain stable performance even at high temperatures

- Independent closed-loop cooling system to control heat efficiently during continuous operation

- Wide voltage tolerance to handle unstable power supply and reduce electrical stress

- Low-RPM airend design for longer life, smoother operation, and lower noise

- Proven performance across Bangladesh industries such as textile & garments, pharmaceuticals, food & beverage, and heavy industries

✅ Result: SCR delivers more reliable uptime and lower long-term operating cost in Bangladesh—where many imported European compressors may face climate-related overheating issues, moisture problems, and higher service expenses.

Industries Using SCR 90kW Screw Air Compressor in Bangladesh

The SCR 90kW industrial air compressor is widely used in:

- Textile & Garments (Spinning, Weaving, Dyeing, Finishing)

- Pharmaceutical Industries

- Food & Beverage Processing

- Chemical & Process Plants

- Ceramics & Tiles Manufacturing

- Paper & Packaging Industries

- Steel & Engineering Workshops

- Cement & Construction Materials

- Feed Mills & Agro-Processing Plants

These industries benefit from stable pressure, clean compressed air, reduced downtime, and lower energy cost.

European-Standard Technology at an Affordable Price

SCR integrates advanced compressor technology normally offered by top European air compressor brands, while keeping investment and operating cost practical for Bangladesh factories.

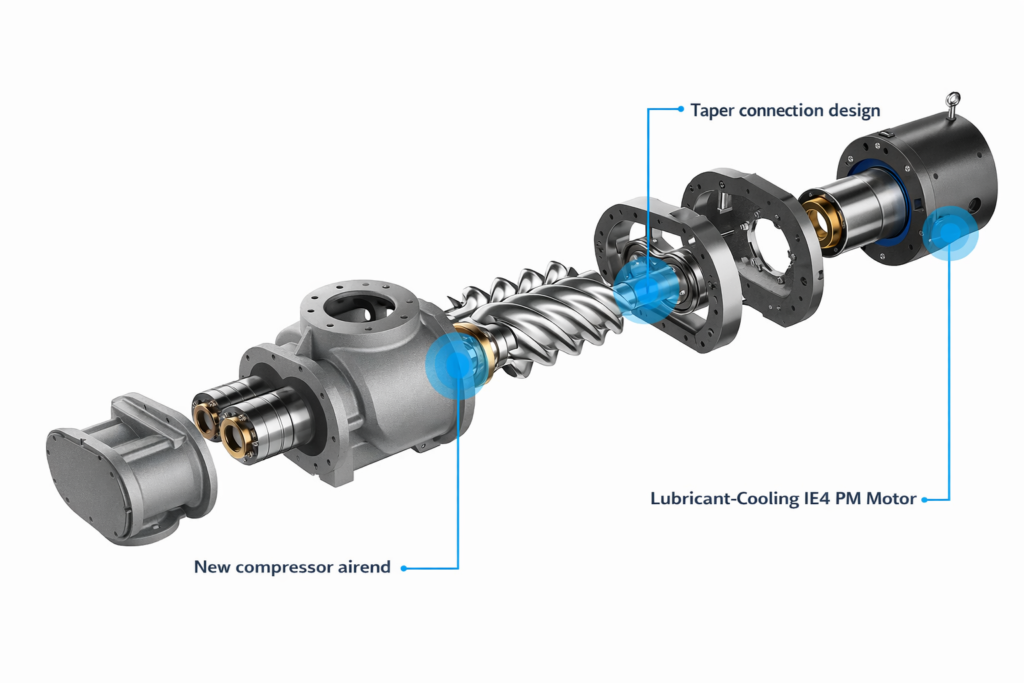

Key Technology Features

- IE4 Super-Premium Permanent Magnet Motor

- Direct Drive System (1:1 Taper Connection) – no belt, no gearbox

- Japanese-designed airend (R&D collaboration with Anest Iwata)

- Isothermal compression with multi-point oil injection

- Double VSD control (main motor + cooling fan)

- Ultra-stable pressure control (±0.01 MPa)

- Oil carryover less than 3 ppm

- 7-inch touch screen controller

- Modbus / RS485 communication

- Soft-start technology to protect electrical systems

SCR vs European Air Compressor – Technical Comparison

| Feature | SCR Screw Compressor | European Brand Compressor |

| Motor Efficiency | IE4 PM Motor | IE3 / IE4 |

| Drive System | Direct Drive (1:1) | Direct / Gear |

| VSD | Standard | Often Optional |

| Pressure Stability | ±0.01 MPa | ±0.02 MPa |

| Oil Carryover | <3 ppm | <3 ppm |

| Energy Saving | 35–40% | 30–35% |

| Spare Parts Cost | Low | Very High |

| Initial Price | Affordable | Expensive |

| Service Cost | Low | High |

➡️ Same performance, much lower total life-cycle cost in Bangladesh.

SCR’s Cloud Service Option – Advance IoT

As the authorized distributor of SCR compressors in Bangladesh, Global Cynax delivers a connected compressed-air solution that combines proven compressor performance with advanced IoT + cloud visibility. Monitor key operating conditions in real time, receive actionable alerts, and protect remote access with enterprise-grade security—so you can reduce unplanned downtime and improve maintenance planning.

🛰️ Real-Time Remote Monitoring

Monitor SCR compressor running conditions anytime, anywhere via cloud access. View key operational status and performance data in real time for faster decisions and better control.

🔔 Smart Alarm Notifications

Receive automatic alarms when abnormal conditions occur. Early alerts support preventive action and help avoid unplanned shutdowns.

🔗 Industrial Connectivity & Integration

Supports industrial communication for integration with plant systems (e.g., RS485 / Modbus RTU). Suitable for centralized monitoring and coordinated multi-compressor operation.

🔒 Secure VPN Cloud Access

Secure remote connectivity using VPN (Virtual Private Network)—providing security comparable to a private network. The cloud platform is designed to be user-friendly for operators and maintenance teams.

Independent Closed-Loop Oil Cooling System — Technical Feature Highlight

The SCR EPM Series IE4 Super-Premium Permanent Magnet Motor uses an independent closed-loop oil cooling system to provide stable, high-efficiency thermal management in demanding industrial conditions. Coolant circulates through a fully sealed circuit, absorbing heat from critical motor components and transferring it to an external heat exchanger before recirculation—delivering consistent cooling performance regardless of motor speed or ambient environment.

Closed-Loop Oil Cooling System

Key technical benefits:

- Sealed cooling loop: prevents dust/moisture ingress and protects cooling performance in harsh environments

- Uniform heat removal: minimizes hotspots, reduces thermal gradients, and improves insulation and bearing life

- Independent thermal stability: reliable cooling during low-speed/high-torque operation and frequent load changes

- Permanent magnet protection: maintains safe operating temperatures to reduce demagnetization risk and preserve efficiency

This design supports IE4 super-premium efficiency, improves reliability, and helps reduce total lifecycle cost.Low Spare Parts Cost & Easy Maintenance

For most factories in Bangladesh, the true cost of an air compressor is not only the purchase price—it’s the maintenance cost, spare parts cost, and downtime risk over the next 5–10 years. Many European air compressors depend on proprietary spare parts and expensive imported consumables, which often means longer lead times when a part fails. In real factory conditions, that can translate into long downtime, production interruption, and higher overall operating expense.

SCR is designed to avoid these common ownership problems. In Bangladesh, SCR users typically experience 30–50% lower spare parts cost compared to European brands. Maintenance is also simpler because SCR uses a service-friendly direct drive design—with no belt and no gearbox, there are fewer wear components, fewer breakdown points, and faster servicing. Most importantly, Global Cynax stocks original SCR spare parts locally, ensuring quick availability and minimizing downtime when parts are needed urgently.

Key benefits of SCR in Bangladesh:

- Lower spare parts cost (30–50% less) compared to European compressors

- Original spare parts stocked by Global Cynax for quick supply

- Simple, service-friendly design for easier maintenance

- Direct drive system (no belt, no gearbox) → fewer wear parts and reduced failure risk

- Less downtime, lower maintenance expense, and better operational continuity

✅ Result: SCR delivers one of the lowest total life-cycle costs (LCC) for industrial air compressors in Bangladesh—making it a smarter long-term choice for factories that value reliability and cost control.

Technical Specifications – SCR 90kW Screw Air Compressor

| Parameter | Specification |

| Motor Power | 90 kW |

| Motor Type | IE4 Permanent Magnet, Oil-Cooled |

| Drive Type | Direct Drive (1:1 Taper) |

| Working Pressure | 7 / 8 / 10 bar |

| Air Capacity | ~13.8 – 14.4 m³/min |

| Controller | 7” Touch Screen, VSD |

| Oil Carryover | <3 ppm |

| Protection Class | IP65 |

| Design Life | 100,000+ hours |

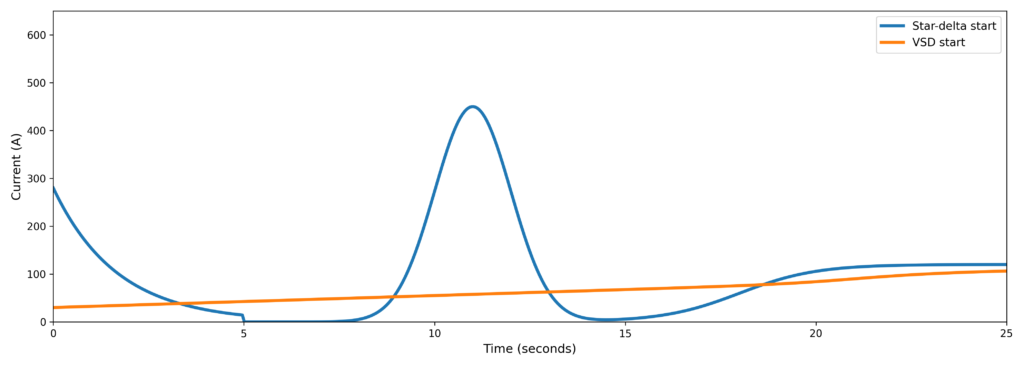

Energy Saving Technology

A soft-starter system reduces inrush current during startup. The SCR APM Series uses soft-start technology at startup. The Inovance VSD limits starting current to approximately 1.5 times the full-load current (FLC). In contrast, traditional motor starters—such as direct-on-line (DOL) and star-delta starters—place a heavy load on the power supply because their peak starting current is typically 8–10 times FLC. With a variable-speed soft-start system, the starting current does not exceed the rated value.

The SCR compressor can automatically adjust compressor speed based on real-time factory demand using an in-house control algorithm. This enables it to deliver the exact airflow volume and pressure required while maximizing energy savings. Energy efficiency is maintained across all load conditions through wide-range inverter control, wide-range speed regulation, and an e-STOP function.

Star Delta Vs VSD Technology

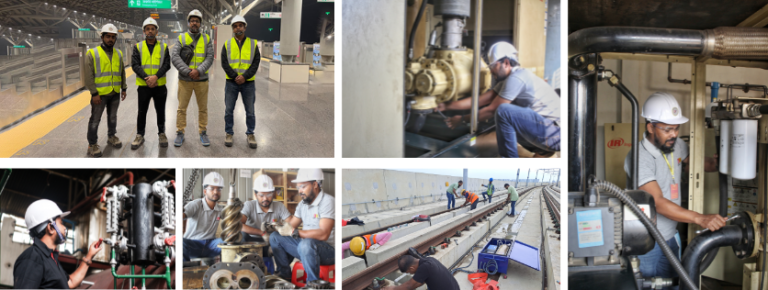

Strong After-Sales Service Support by Global Cynax

As the authorized SCR compressor distributor in Bangladesh, Global Cynax provides unmatched after-sales support:

- 17-member trained service team

- Dedicated service vehicles

- Fast spare parts supply

- Preventive & emergency breakdown service

- AMC (Annual Maintenance Contract) available

- Service teams in Dhaka & Chattogram

- Installation, commissioning & operator training

➡️ Ensuring minimum downtime and long-term peace of mind.

Why Buy SCR Compressor from Global Cynax?

✔ Authorized distributor in Bangladesh

✔ Genuine SCR compressors & spare parts

✔ Strong nationwide service network

✔ Energy-efficient solutions

✔ Competitive pricing

✔ Long-term technical support

Contact Global Cynax Bangladesh Ltd.

Authorized SCR Air Compressor Distributor

📱 Mobile: +8801786100017, +8801933555248

📧 Email: [email protected]

🌐 Website: www.globalcynax.com