Global Cynax—Camfil’s authorized channel partner and distributor in Bangladesh—delivers world-class gas turbine filtration for combined-cycle power plants and other gas-fueled facilities. As a global leader in air filtration, Camfil provides advanced systems that boost turbine efficiency, cut downtime, and lower maintenance costs. Whether for new builds or retrofits on GE, Siemens, Mitsubishi, or other OEM turbines, we supply proven filtration solutions that protect your turbine investment and enhance overall plant performance.

Why Choose Camfil Gas Turbine Filters?

- Optimized Turbine Performance: Cleaner air intake means higher output and better efficiency.

- Extended Equipment Life: Protects compressor blades and hot gas path parts from fouling, erosion, and corrosion.

- Reduced Maintenance Costs: Fewer unplanned shutdowns and longer service intervals.

- Energy Efficiency: Lower pressure drop ensures turbines run at peak capacity.

- Proven in Harsh Conditions: Designed for Bangladesh’s high humidity, dust, and coastal environments.

Camfil Gas Turbine Filter Solutions in Bangladesh

Global Cynax, the authorized Camfil partner in Bangladesh, provides a complete range of Camfil gas turbine filters designed to deliver reliable protection and efficiency for combined cycle power plants and industrial gas turbine users. As a trusted gas turbine filter supplier in Bangladesh, we ensure plant operators get the right filtration solution for their unique operating environment.

Camfil EPA & HEPA Gas Turbine Filters

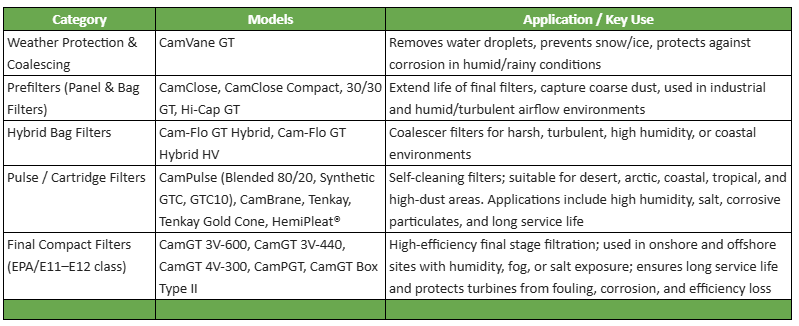

Camfil’s EPA and HEPA turbine filters are engineered according to the latest ISO 29461 standards. These high-efficiency particulate filters capture fine and submicron particles that cause fouling and performance degradation in compressors. With designs such as the CamGT 3V-600, CamGT 3V-440, and CamGT 4V-300, operators benefit from:

- Vertical pleat construction ensures stable performance even in humid or coastal conditions.

- Ultra-low pressure drop, improving turbine efficiency and reducing fuel consumption.

- Output ratings above 98.8% efficiency with reduced CO₂ emissions per MWh. These filters are trusted in combined cycle power plants (CCPPs) worldwide for their ability to keep engines clean and extend service life.

Camfil Static & Pulse Filters for Gas Turbines

For dusty, desert-like, or industrial environments, Camfil offers advanced static and pulse-cleaning filter systems. Solutions like the CamPulse GTC and Tenkay filters are designed with:

- Self-cleaning pulse technology that extends filter life and reduces change-out frequency.

- Media options such as synthetic GTC (excellent in coastal humidity), blended 80/20 media (ideal for desert/dust), and CamBrane T12 membrane filters for ultimate submicron particle removal.

- Proven performance in heavy dust load areas, ensuring consistent airflow and protecting turbines from erosion and fouling.

Camfil Hydrophobic & Corrosion-Resistant Filters

In Bangladesh’s coastal and high-humidity environments, such as power plants located in Bhola and Chattogram areas, Camfil’s hydrophobic and salt-resistant filters are a must. Models such as CamPulse CamBrane (T12) and CamGT hydrophobic media filters offer:

- Superior protection against salt-laden air, chlorides, and moisture, preventing hot corrosion of turbine blades

- Stable pressure drops throughout filter life thanks to advanced drainage design.

- Construction with multi-layer membranes that block both wet and dry contaminants.

These filters deliver longer service intervals while securing turbine output in the toughest conditions.

Camfil Upgrade & Retrofit Solutions

Global Cynax helps operators upgrade older filter houses with Camfil retrofit filter systems that integrate seamlessly without major structural modifications. Retrofit solutions include:

- CamGT Box Type II Filters – easily replace older box-type filters with high-performance Camfil designs.

- Spacer Frame Adaptations – permanent frames that allow standard CamGT filters to be installed efficiently.

- Retrofit solutions that immediately lower life-cycle costs by reducing fouling, lowering CO₂ output, and cutting energy losses.

- Camfil EPA & HEPA Gas Turbine Filters – High-efficiency particulate air filters engineered to remove fine and sub-micron particles from turbine intake air. These Camfil turbine filters improve compressor cleanliness, minimize fouling, and extend turbine life, ensuring maximum performance for power plants.

- Camfil Static & Pulse Filters for Gas Turbines – Designed for challenging environments with high dust levels, these Camfil filters provide durable, long-lasting protection. Pulse filters feature self-cleaning technology, reducing maintenance downtime and delivering consistent airflow even under severe dust conditions.

- Camfil Hydrophobic & Corrosion-Resistant Filters – Optimized for coastal and high-humidity sites in Bangladesh, these gas turbine filters block salt, moisture, and corrosive particles. By preventing hot corrosion and water ingress, they safeguard turbine blades and critical components, ensuring reliability in harsh climates.

- Camfil Upgrade & Retrofit Solutions – Global Cynax also supports power plants with retrofitting services, upgrading older filter houses to Camfil’s latest high-performance gas turbine filter technology. This allows operators to reduce lifecycle costs, improve efficiency, and enhance turbine output without major infrastructure changes.

With Global Cynax as your gas turbine filter supplier in Bangladesh, you benefit from Camfil’s world-leading clean air solutions, backed by local expertise, technical support, and after-sales service.

Contact Global Cynax – Your Turbine Filter Partner in Bangladesh

Whether you operate a combined cycle power plant or supply filters in Bangladesh, Global Cynax provides Camfil turbine filtration solutions that ensure higher reliability, lower costs, and reduced environmental impact.